PRODUCTS

QFBO horizontal parting automatic moulding machine

1, Features: 1. High degree of automation: the whole molding line can be operated by 1-2 people (except pouring); br / 2. High efficiency, energy saving, environmental protection: The modeling speed is fast, 110-120 model/hour, small power

Message inquiry1, Features:

1. High degree of automation: the whole molding line can be operated by 1-2 people (except pouring); < br / > 2. High efficiency, energy saving, environmental protection: The modeling speed is fast, 110-120 model/hour, small power consumption; < br / > 3, modelling of good quality: in the process of modelling, sand box, mold placed, turn 90 degrees, the host from the parallel shoot sand sand mold shot down, reduce the wear and tear, mould Angle design is unique, shoot sand sand compaction plate can be reflected in the corners on the far side of sand, sand filling performance is good, modelling of good quality and high output. < br / > 4, sand mold height can be switched three levels: according to the height of casting, sand mold thickness can be selected thin, medium, thick three blocks, save the amount of sand, reduce the production cost; < br / > 5. Loose sand performance requirements: this machine shoots sand from top to bottom with little resistance; < br / > 6, one-time investment, 10 years will not be eliminated. < br / > 7, can also step by step investment host, auxiliary line, pouring machine. < / p >

2, the parameters

| Mold size | 508×610×400(Upper box 130-200 Lower box 130-200 three-stage switch) |

| Modelling methods | Turn the sand box 90 degrees |

| Air jet sand + gravity sand | |

| Ejector + compaction | |

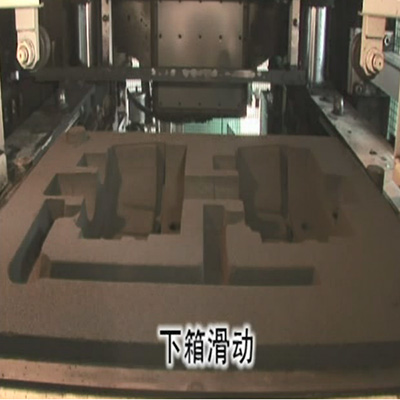

| The core method | The lower case slides out of the lower core automatically |

| Compaction driven | Hydraulic drive |

| Compaction pressure | 1Mpa |

| Modelling speed | Model 120 / h |

| Air consumption | 1.2Nm3/mold |

| Work pressure | 0.5-0.55Mpa |

| Power source specification | Dynamic voltage AC380V(50HZ), operating voltage AC100V(50HZ) |

| Casting weight | 117-201kg(MAX) |

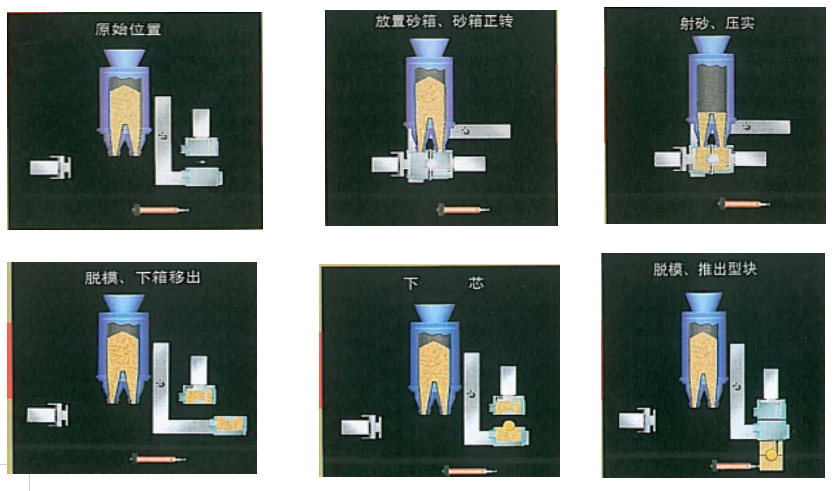

3, molding process

|

|

|

|

The lower box slides out the lower core/Siemens operating system and fault diagnosis display screen

QFBO horizontal parting molding machine participated in China International casting Expo, Weifang casting exhibition, north casting exhibition